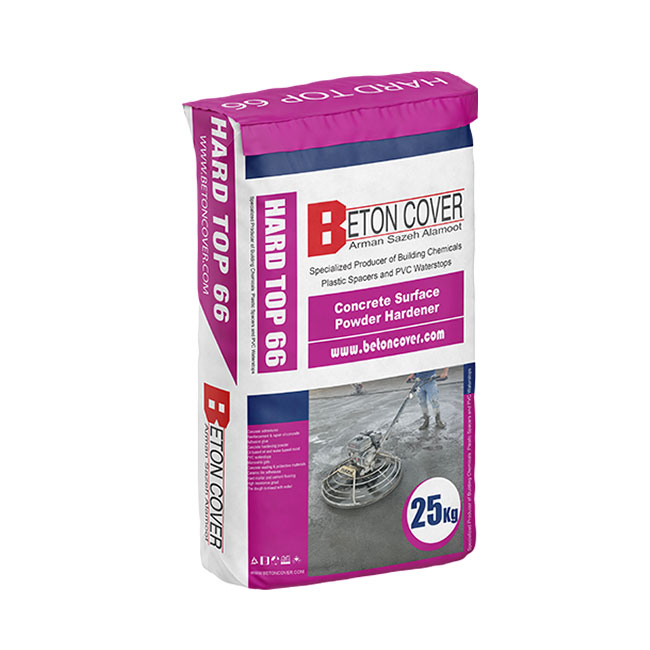

Concrete Surface Powder Hardener – HARDTOP 66

Hardener of fresh concrete surface by dry spraying method.

HARDTOP 66 is a one-component product that is sprayed on fresh concrete by dry spraying method. This product is used to create uniform and polished concrete surfaces with high mechanical resistance in order to resist abrasion and impact.

Physical and chemical properties

Physical state Powder

Color Types of colors

Density 1.8 gr/cm³

Final compressive strength 70 N/

Properties and effects:

It does not contain chlorine ions

Very durable and light finish

Very high adhesion to the concrete below

No shrinkage or cracking

Resistant to static, dynamic and impact vibrations

Resistant to sunlight, rain and other environmental factors

Quick and easy implementation

Increasing compressive and wear resistance

Application:

Flooring of warehouses, factories and parking lots

Reinforcement of concrete floors, which must have a hard and wear-resistant floor

Paving surfaces with heavy traffic

Consumption:

The amount of HARDTOP 66 consumption is determined based on workshop conditions. The recommended dose for each square meter is 3 to 7 kg.

Technical points:

Before use, it is necessary to observe a few points:

The grade of floor concrete should be at least 300.

The floor concrete slump should be between 7 and 10.

Aeration of floor concrete should not be more than 4.

The water-cement ratio of the floor concrete should be between 40% and 50%. If necessary, concrete water reducers such as super reducers should be used.

consumption instruction:

Apply this product after concreting is finished and after the concrete surface is semi-dry. Depending on the intended use, sprinkle HARDTOP 66 powder on the concrete sections by dry spraying to absorb the moisture of the concrete. As soon as the color of the sprayed powder changes, smooth the surface with a trowel, then in order to achieve a smooth and uniform surface with proper resistance, it is necessary to smooth the final surface using an electric (butterfly) trowel. It is very important to maintain the necessary moisture in the surface and to prevent cracking, maintenance and curing of the surface after the final troweling. For this purpose, after finishing troweling, spray water on the work surface and treat it. In ambient temperature over 30 degrees, it is recommended to use a curing product to maintain the moisture on the surface.

Maintenance:

It can be stored in the original packaging and in a covered warehouse away from direct sunlight at a temperature of 10-30 degrees Celsius for one year after the date of manufacture.

packing:

25 kg bag

safety tips:

This material is not flammable and is not harmful to the environment. Avoid contact with eyes and skin. In case of contact with eyes, wash with plenty of fresh water. It is recommended to use protective glasses and gloves while working. If swallowed, consult a doctor immediately.

Reviews

There are no reviews yet.