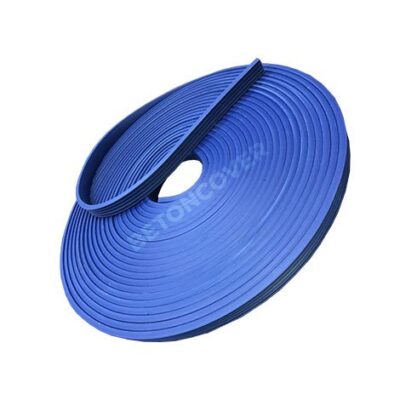

PVC WATERSTOP

Resistant and flexible layer of PVC materials suitable for cold and expansion joints of walls and floors.

Waterstop is a flexible sealing tape that is used to seal concrete and expansion joints and operational seams. This product is made of high-quality PVC raw materials and based on DIN and ASTM standards in width and thickness. Diverse models are designed and produced according to the conditions of the cutting site and the pressure applied to the concrete.

Physical and chemical characteristics:

physical state Flexible solid

color yellow/ orange/ blue

Density 1.3 gr/cm³

Tensile strength > 10 MPa

Elongation > 300%

Model E, O,EF,OF

Thickness 2.5-10 mm

Width 15-50 cm

Properties and effects:

High quality PVC raw materials

Stability after installation is equal to the life of the structure

Resistant to alkalis and acids

Longitudinal and transverse tensile strength higher than the standard

Resistant to hydraulic pressure and contraction in hollow models

Application:

Sealing hydraulic structures

Pools, dams, concrete liquid tanks, canals, water and sewage pipes

Sealing the expansion and execution joints of concrete buildings and water structures such as walls and floors

In accordance with the standards:

ASTM D412 – ASTM D570 – ASTM D624 – ISRI 13277 – ISIRI 13277 – ASTM D747 – ASTM D792 – CRD-C570 – CRD-C573 – CRD-C572

How To Install PVC Waterstops:

To connect the water stop in the way of the rebars, you must use a special clip for the water stop. The flat water stop is used in the places where the concrete break is predicted and the hollow type is used in the places where the expansion joint is predicted so that half of its width is buried in the first concreting and the other half in the second stage concreting.

Tools For Connecting PVC Waterstops:

Clamp: for fully connecting PVC water stops to the armature (it is possible to produce punched edges without the need for clamps)

Hoya Tabari: to connect the two ends of the water stop

Adhesive: to connect the two ends of the water stop

How To Install Two Ends Of PVC Waterstops:

In order to increase the reliability of the sealing, in the parts where it is necessary to connect the two ends of the water stop to each other, the following two methods are used:

1-Cold welding: after shaving the treads of the two edges of the water stop about 40 cm, apply special PVC adhesive to the two parts of the water stop and place them on top of each other and place a 50 kg weight on it for 8 to 12 hours. Data to attract each other.

2- Hot welding: we melt the two ends of the water stop with the ax device and immediately stick them together.

Maintenance:

It can be stored in the original packaging and in a covered warehouse away from direct sunlight at a temperature of 10-30 degrees Celsius for six months after the date of manufacture.

packing:

Vacuumed rolls of 25 meters

safety tips:

This material is flammable and not harmful to the environment.

Reviews

There are no reviews yet.